The horizontal milling machine was developed in 1818 by American Whitney. It was in 1884 when American Brown made the first-ever universal milling machine that serves as the elevator milling machine's prototype.

The gantry milling machine was introduced around 1884. It was during the 1920s when the semi-automatic milling machines started to show up. The workbench used the stoppers for performing automatic conversion of fast-feed or feed-fast.

What is a Gantry Milling Machine?

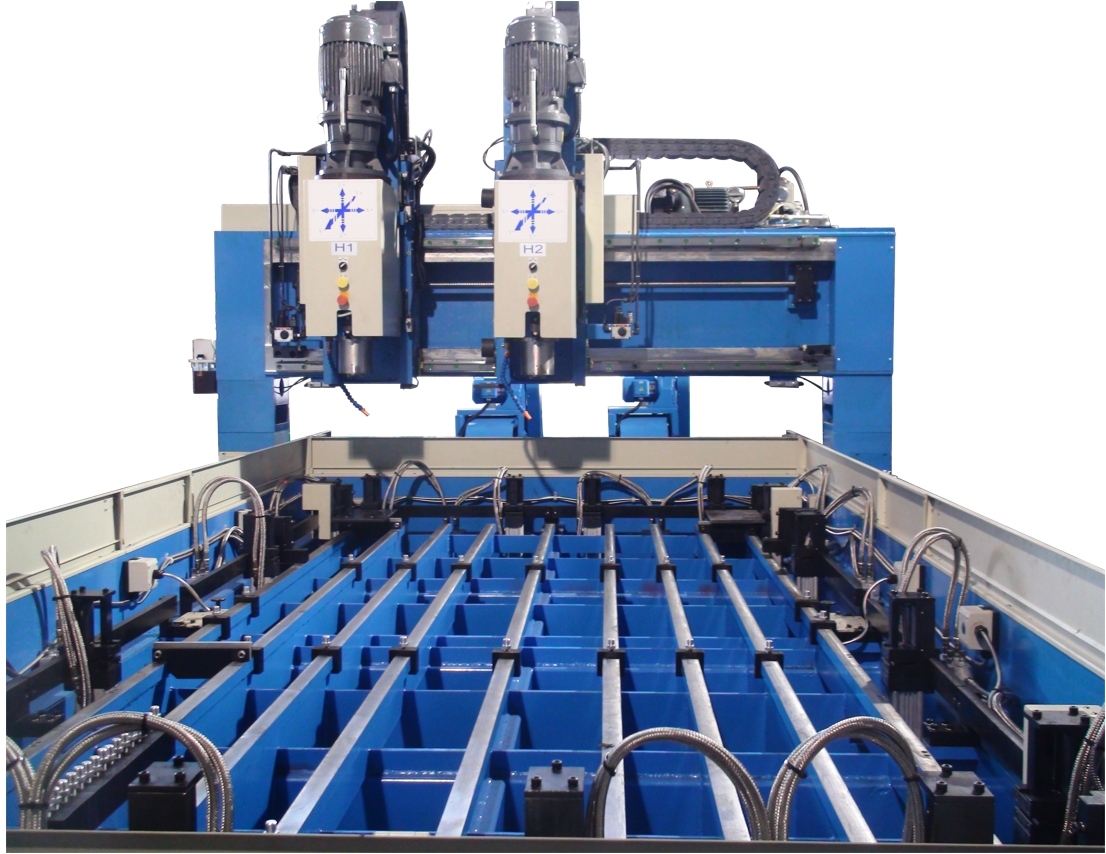

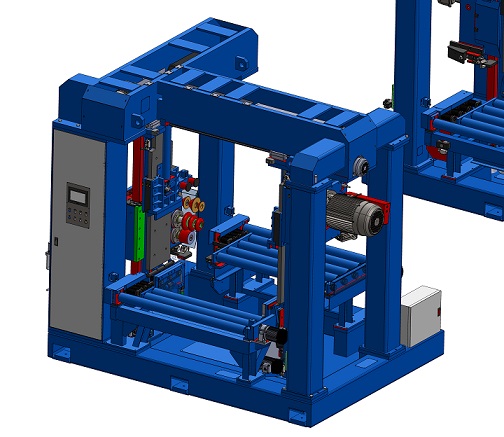

A gantry milling machine, or also called gantry milling, is a type of milling machine with a horizontal long bed and a gantry frame.

The surface on the gantry milling machine can be simultaneously machined with several multiple cutters. Production efficiency and processing accuracy are relatively high. It is also suitable for beveled and flat surfaces for big workpieces in mass and batch production.

A gantry milling machine also has the ability to process some special parts and space surfaces. There are now several variants of gantry milling machine suitable for different workpieces.

Gantry Drill and Milling Machine

Milling and drilling operations could be done by mounting a powerhead on the beam then loading the milling or drill cutter through the post.

The bed of a gantry milling machine is equipped with the X-axis guide rail, with the gantry milling machine is attached to the bed.

A gantry frame is found above the workbench. The gantry also includes the gantry carriage that is clamped on an X-axis rail. There is a Z-axis guide rail mounted on the gantry. There is a beam provided with the Z-axis carriage.

This beam is also movably clamped by the Z-axis carriage to the Z-axis guide. The Y-axis guide rail is mounted on the beam as well.

The gantry drill and milling machine have a milling device that is arranged on a Y-axis guide rail for the gantry frame to be subjected to a three-dimensional space milling processing of Z, Y, and X under the numerical control system's control.

A CNC portal milling machine provides high precision, boring, cutting, drilling, and milling operations.

Gantry Boring and Milling Machine

A beam is equipped with a boring milling and milling head. The primary shaft, or ram or sleeve, is usable for an axial motorized feed with a fine motion adjustment device. A fine adjustment speed could go as low as 5mm per minute. Both milling and boring operations are feasible.

Difference

The portal milling machine has a similar shape to a planer. The main difference is that the column and beam don't feature a planer holder and instead, it has a milling cutter with the spindle box. The reciprocating motion of the gantry milling machine's longitudinal table is not the primary motion. However, the milling cutter's rotary motion and the feed motion is the primary motion.

Structure

A portal milling machine is made up of a door frame, an electrical control system, and a bed table. A portal frame is made up of a top beam and a column with a beam at the center. This beam is movable up and down along two-column guide rails.