Top Auto Parts Aftermarket Suppliers

Suppliers of aftermarket auto parts make up one of the biggest branches of today's automotive industry. They manufacture, distribute, and trade aftermarket vehicle parts, accessories, and equipment to meet the specific needs of consumers.

Take a look below to know some of the top auto parts aftermarket suppliers in the market right now in no particular order:

AC Delco

General Motors owns AC Delco, an American manufacturing company. AC Delco specializes in the production of General Motors OE as well as aftermarket parts for many other car makers. It is among the oldest companies in the industry of auto parts that has been in business for more than a century.

Continental AG

With its headquarters located in Hannover, Germany, Continental AG is a German multinational manufacturer of automotive parts. They specialize in manufacturing braking systems, tires, chassis component, powertrain, electronics components, and automotive safety.

Denso Corp.

The Japan-based Denso Corp is one branch of Toyota Group of companies that operates in more than 35 countries across the globe. They are popular for production of OEM auto parts such as powertrains, communication and information systems, and climate control system components.

Hyundai Mobis

The South Korean aftermarket parts supplier Hyundai Mobis forms the service and part branch of Hyundai Motors, General Motors, and Kia Motors. Hyundia Mobis manufacturers all auto body parts of Hyundai and Kia's aftermarket parts like the Kia rear door mirror. Some of their products include front-end modules, chassis, airbags, cockpits, and more.

Lear Corp.

Founded as American Metals Products, Lear originally produced welded, stamped, and tubular steel assemblies for aviation and automotive industries. Their name was changed in May 1996 to Lear Corporation as a company that specializes in car electric systems and interiors.

The company supplies electrical distribution systems, seating, electronic modules, and software to all the leading car manufacturers in the world.

Magna International Inc.

A leading American manufacturer in the industry of aftermarket performance, Magna International Inc. has been dominating the market for more than 30 years. The company produces mufflers, manifold catalytic converters, and cat-back exhaust systems. They mainly manufacture high performance exhaust products and automotive catalytic converters for SUVs, trucks, BMWs, Cadillac, Chevrolet, Ford, and Toyota.

NGK Spark Plug Co., Ltd.

A branch of NGK Insulators, NGK Spark Plug Co., Ltd. is a globally recognized Japanese company with headquarters in Nagoya, Japan. They manufacture automotive electronics, sensor products, and ignition to the automotive, power, marine, and motorcycle tool markets. Their product lines include spark plugs, glow plugs, oxygen sensors, coils, ignition leads, and more.

Robert Bosch GmbH

BOSCH is the German multinational technology and engineering company and is among the oldest and largest automotive parts manufacturers in the world. There is a big chance that this company produced some of the parts of your car. The distribution centers of BOSCH are found all over the world including North America, Australia, and Asia.

Visteon

The American company Visteon manufactures auto parts for the leading car makers such as BMW, Ford, General Motors, and Daimler that used to be under the ownership of Ford Motor Company before this became independent back in 2000. The product line of the company is categorized to three primary segments namely interior, electronics, and climate systems.

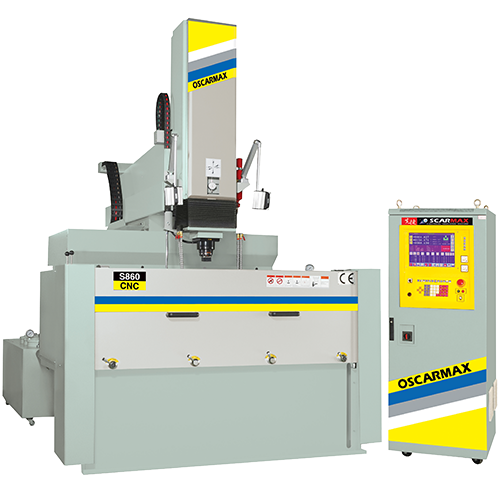

PRODUCTS